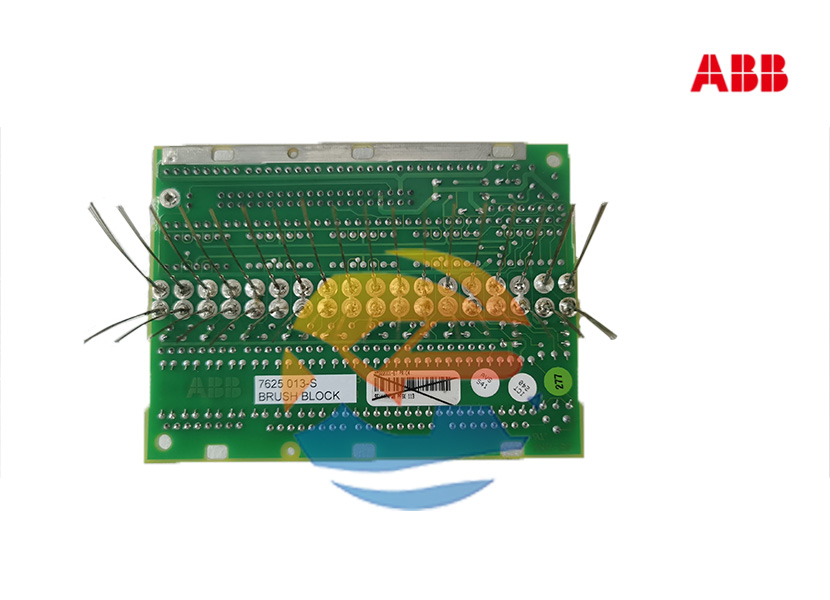

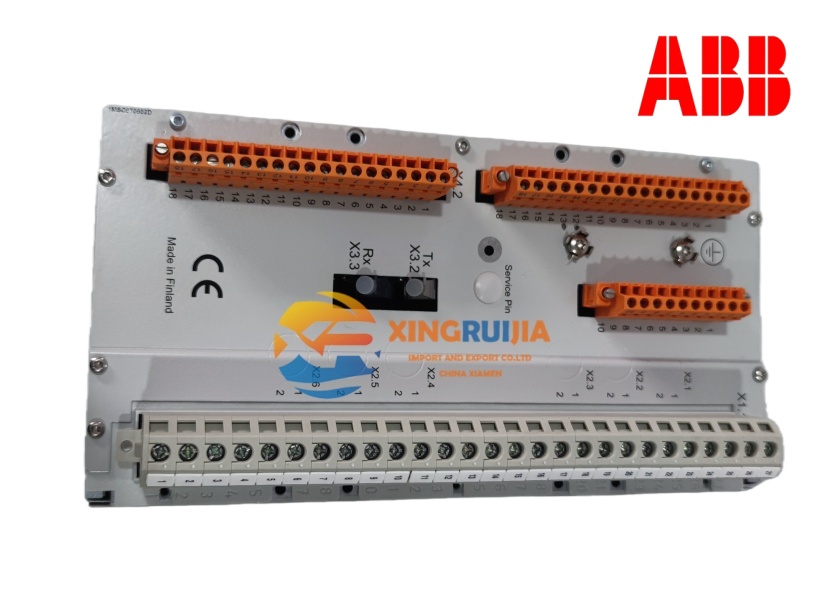

ABB 7625013-S

ABB 7625013-S Combi Controller - Technical Parameters

Primary Function: This module is the main computer and central processing unit for an ABB IRC5 robot controller (specifically the IRC5 Compact and IRC5 Single Cabinet models). It integrates several critical functions into a single unit.

1. Key Integrated Functions

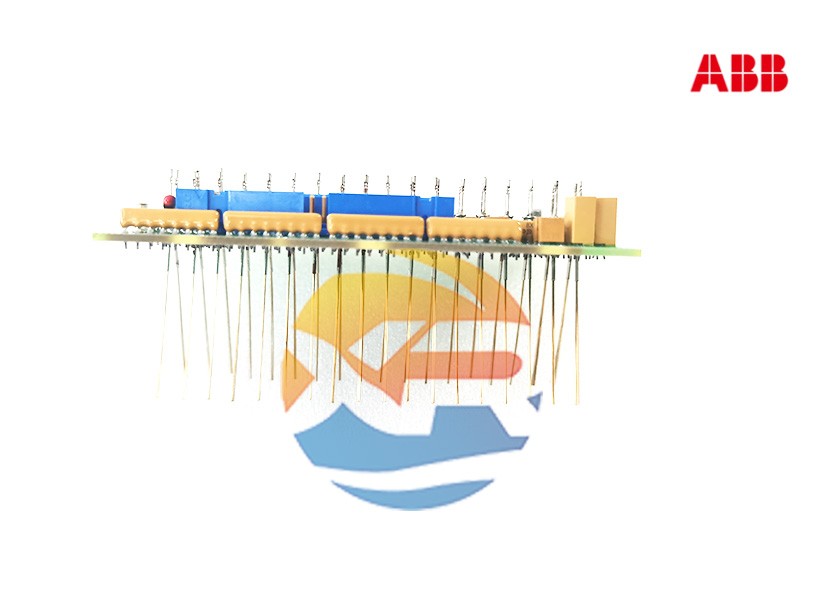

The "Combi" name signifies that it combines the following key components onto one printed circuit board (PCB):

Main Computer (Controller CPU): The central processor that runs the robot's operating system (RobotWare) and executes the application programs.

Drive Module: Contains the power electronics that generate the signals to control the motors on the robot arm. It typically includes the functionality for up to 6 axes (the main robot joints).

I/O Module: Provides built-in Input/Output interfaces for connecting peripheral devices (e.g., sensors, grippers, pneumatic valves, safety interlocks).

Safety Controller: A dedicated processor that independently manages all safety functions (e.g., emergency stop, safety gates, axis limits) to ensure safe operation according to standards like SIL 2/PLe.

2. Detailed Technical Specifications

| Parameter Category |

Specification Details |

| Controller Type |

IRC5 Combi Controller (Integrated CPU, Drives, I/O, and Safety) |

| Intended Robot Models |

Primarily for smaller ABB robots such as the IRB 140, IRB 1600, and other robots typically paired with the IRC5 Compact cabinet. |

| Axis Control |

Controls up to 6 axes (standard industrial robot). Some variants may support an additional integrated 7th axis (e.g., for a linear track or positioner directly controlled by the Combi unit). |

| Input Power |

200-600V AC, 3-phase, 50/60 Hz. The specific voltage range depends on the unit's configuration and region. |

| I/O Capacity |

16 Digital Inputs

16 Digital Outputs

2 Analog Inputs

2 Analog Outputs

(These are the built-in I/Os. Significantly more I/O can be added via optional fieldbus adapters like Profibus, Profinet, DeviceNet, EtherNet/IP). |

| Communication Interfaces |

• Ethernet (for programming, PC interface, and network communication)

• RS232 (for serial communication, often used for legacy devices)

• Fieldbus Adapter Slots (typically 2 slots for adding optional communication cards). |

| Safety Functions |

• Dual-channel Emergency Stop

• Safety Stop (SS1, SS2)

• Auto Stop

• Supervisory Safety Stop

• Axis-specific Safe Speed and Safe Position monitoring

• Safety-rated monitored outputs (SMO) |

| Memory |

Varies based on the RobotWare version and specific order, but typically includes Flash memory for the system and RAM for program execution. Exact MB/GB values are model-year specific. |

| Physical Dimensions |

Designed as a slide-in module for the IRC5 Compact cabinet. Exact dimensions are proprietary to the cabinet chassis. |

| Weight |

Approximately 15 kg (33 lbs) (weight can vary slightly). |

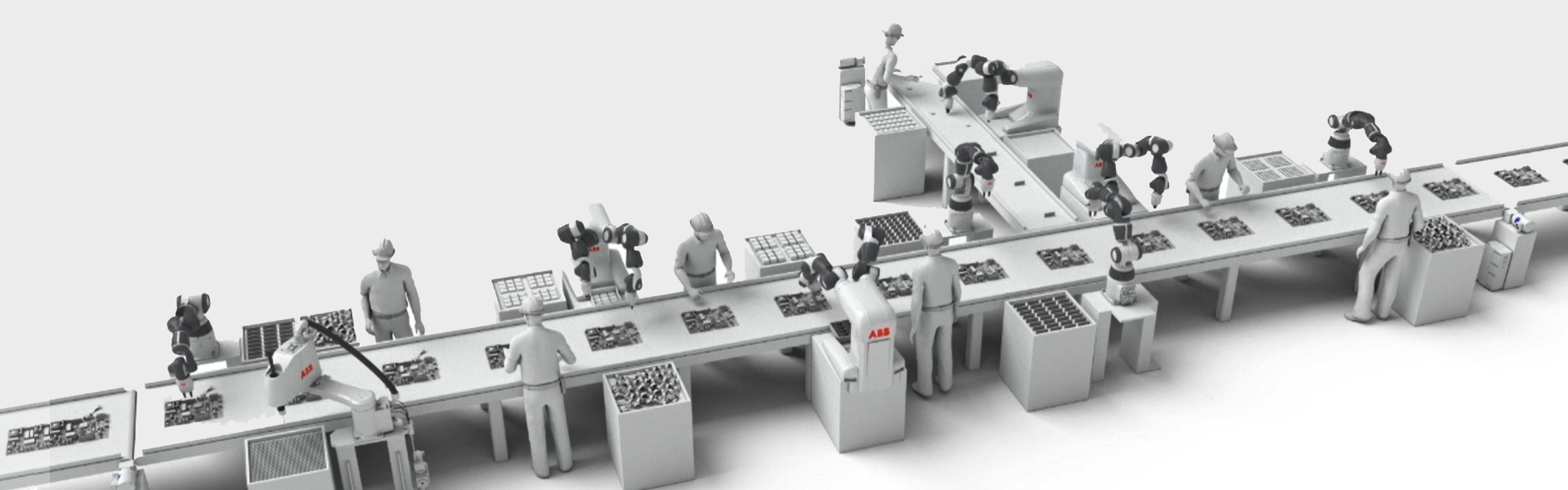

3. Common Applications

This controller is used for automating tasks with small to medium-sized industrial robots, including:

Material Handling: Pick and place, packing, palletizing.

Machine Tending: Loading/unloading CNC machines, injection molding machines.

Arc Welding: Coordinating the robot and welding equipment.

Assembly: Precise component assembly tasks.

Dispensing: Applying sealants, adhesives, or paints.

Inventory//Affordable prices//Excellent quality//Imported with original packaging

===================================================================================================================================================================

First hand source//affordable price//Spot inventory!

•Shipping Port: Xiamen

•Manager: Rhonda

•E-mail: sales7@saulplc.com

•Tel/WhatsApp/Wechat: + 86-15359273796

•Ship to you via Fedex/DHL/TNT/UPS/EMS

•Package: Original packing with cartons

Sweden

Sweden